Flexible Bracket for Robotized Spot Welding Pliers

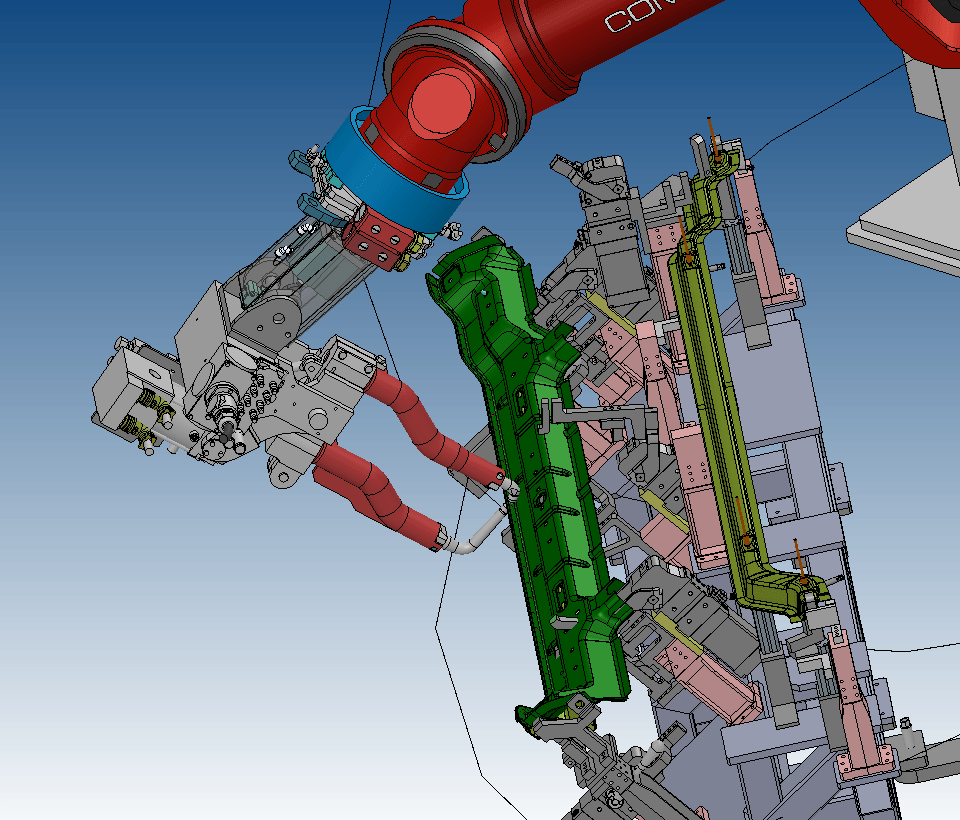

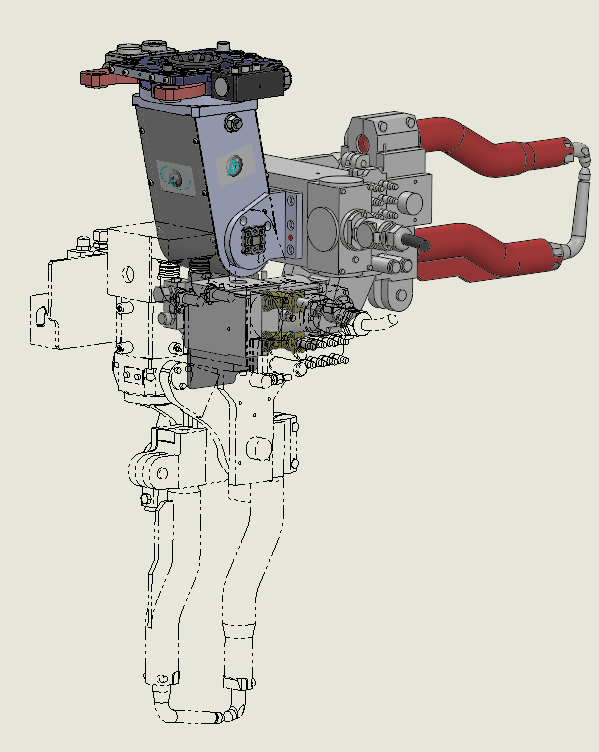

This solution considerably simplifies all the CAD simulation procedures, reducing the costs of structures. The intelligent flexible bracket, driven by a brushless synchronous motor, allows interpolation with the axes of anthropomorphic and Cartesian robots, reducing cycle times lost for tool changes, and for the movements of additional axes that move the elements to be welded, as well as the pincer attachment system with flexible bracket simplifies the entire welding cycle by positioning the welding gun as the seventh axis of an anthropomorphic robot. Last but not least, with a single robot and a single welding gun, it is possible to carry out welding on completely different elements and equipment, even with elements positioned vertically and horizontally on different equipment.

Benefits:

Special 3D CAD simulation systems are used in the industry to trace the welding path, highlighting all the field limits of anthropomorphic or Cartesian robots and the accessibility singularities of the welding trajectories. With these simulators the trajectories are obtained, which highlight the reachability limits of the robotic kinematics, for which it is forced to use more identical grippers with different attachments, exploiting the automatic gripper change between robot and grippers already existing in the sector. These constraints are determined by the constraint position of the junction bracket between the grippers and the robot, so there are always limits in the trajectories to be reached, and in many cases one is forced to make the robots work at the limit of its fields of action, also twisting the robot axes between them, increasing their cycle times.

In cases where the reachability of the trajectory is compromised, it is necessary to change the collet with different attachment systems, in practice increasing the cycle times for the tool change (collet) and increasing the costs for a new collet, new attack and change. automatic tool.

In many cases in the sector additional axes are used to be able to position the elements to be welded in various angles, also moving the elements as well as the welding guns in order to give access to the robots, adding costs and important software and hardware resources. In particular, when there are elements for horizontal and vertical welding, and used in the sector, use an axis of rotation of the elements that positions them from horizontal to vertical or intermediate angles, called welding lathes or as they say in the jargon "Tromell", which they can be avoided with the AP Flexible Bracket.

Richiedi i file in 3d, Step, Iges, Parasolid, Solid Work 2018.

1st Flexible Bracket with Pneumatic movement for 90 ° ON OFF rotation.

2nd Flexible bracket with motorized movement Positioning axis from 0 to 90 ° with degree by degree reang.

3rd Flexible Bracket with motorized movement Axis interpolated with the Robot of all brands.

Fill in the fields, and in the message indicate the type of clamp used, the weight and the type of flexible bracket 1, 2, 3.