Standard products for automation

Automation by definition can never be completely standardized, because it is suited to the needs of the customer and the sector, and for this reason it must be accompanied by a multitude of products and automation parts specifically designed, following the ISO standards, in order to guarantee the '' interchangeability between them, creating significant benefits for both the automation manufacturer and the end customer.

Product list

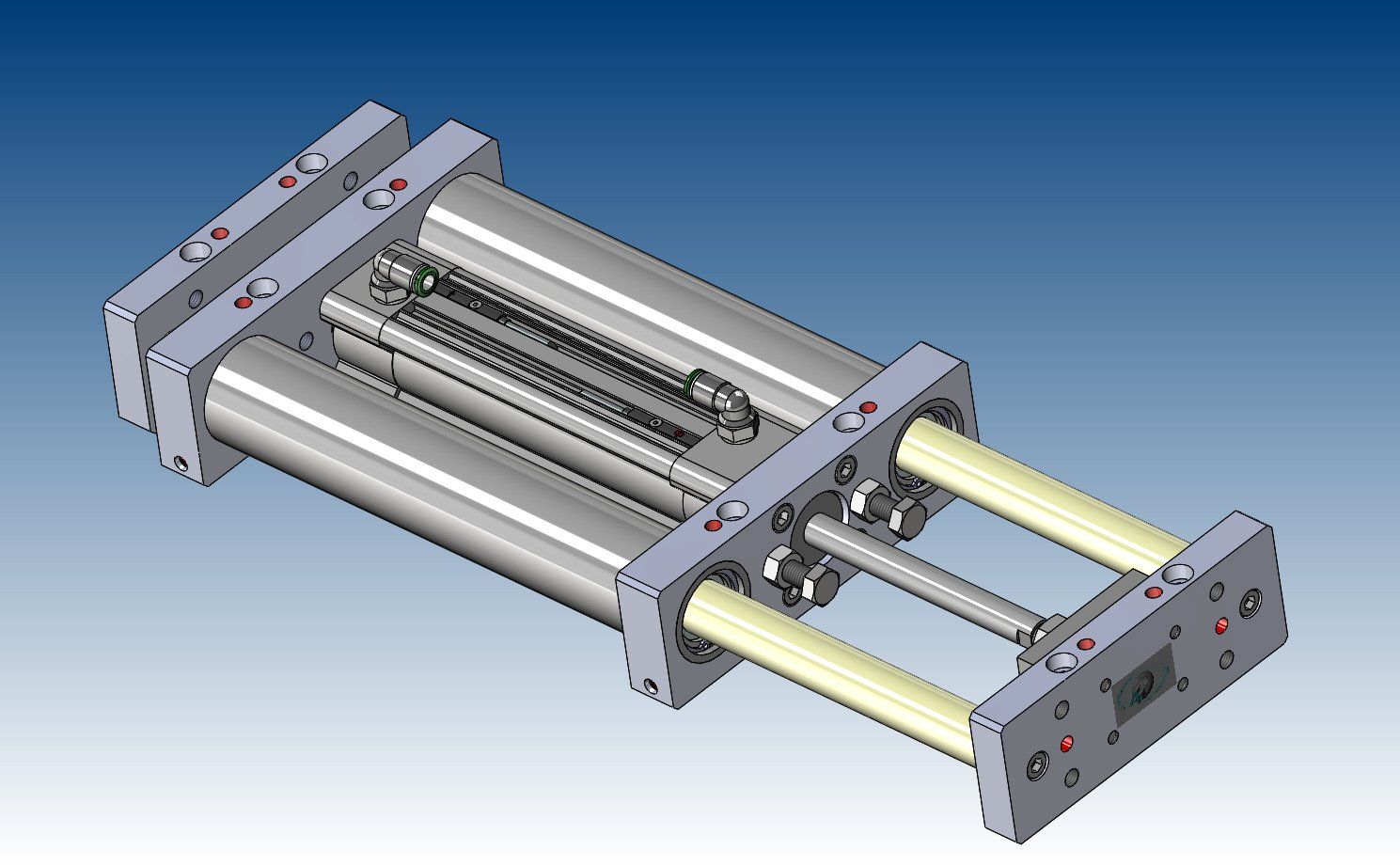

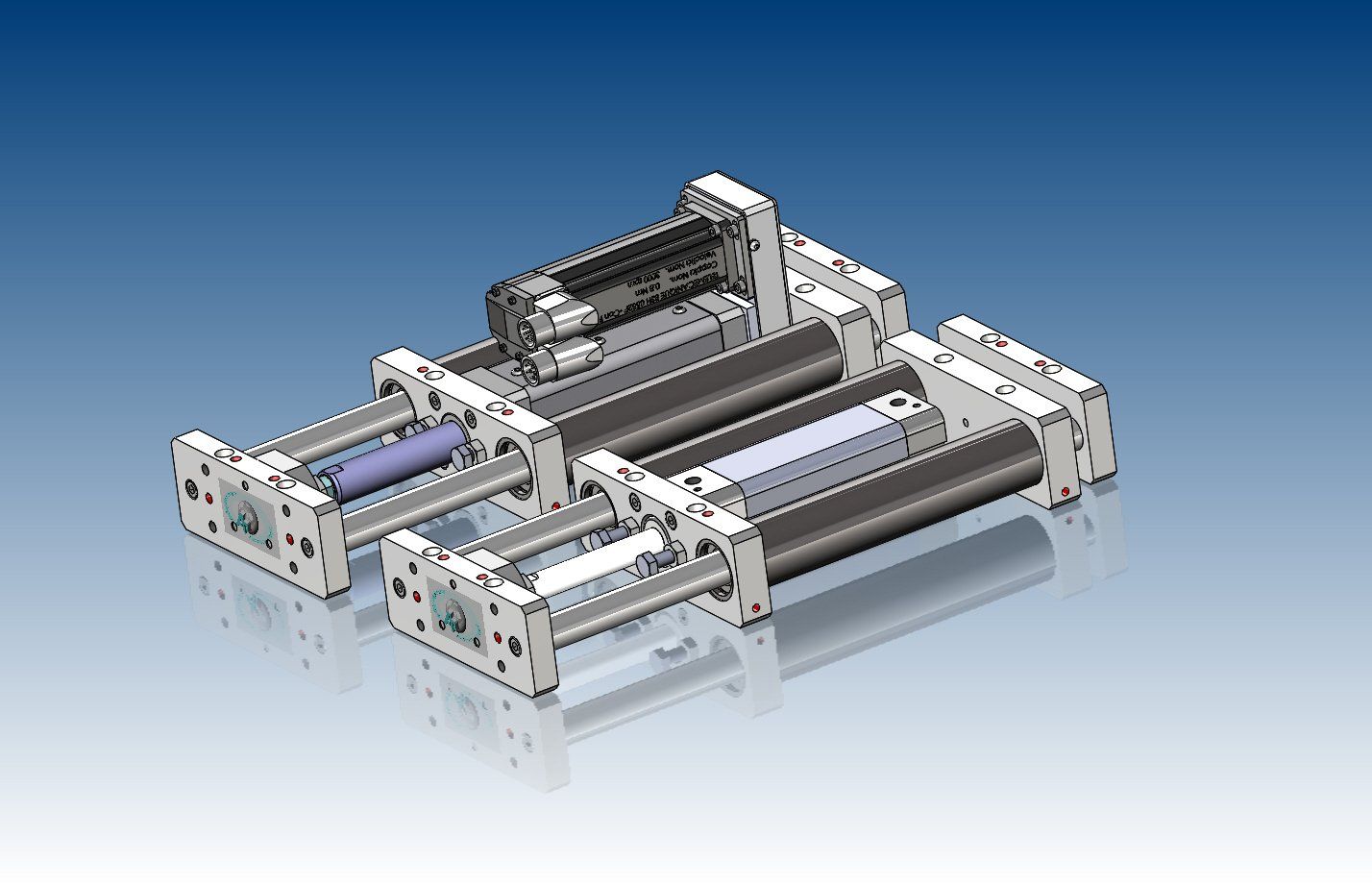

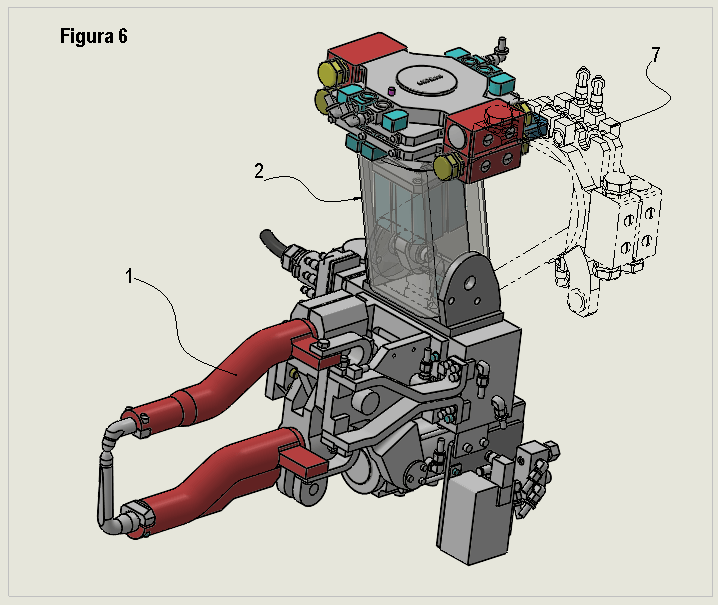

Standard linear slides Operated by ISO interchangeable commercial pneumatic cylinder, with the best European brands. The guides are also interchangeable to adapt to all sectors, from clean rooms, to cement factories and foundries, suitable for dusts, high humidity, etc. Completing a range of IP68 Universal Slides. VDMA ISO 6431-6432 standard

This system, compared to single-brand commercial slides, gives a series of great technical, economic and commercial advantages, both for the builder of automation systems and for the final customer.

Read the benefits listed in the commercial sheet.

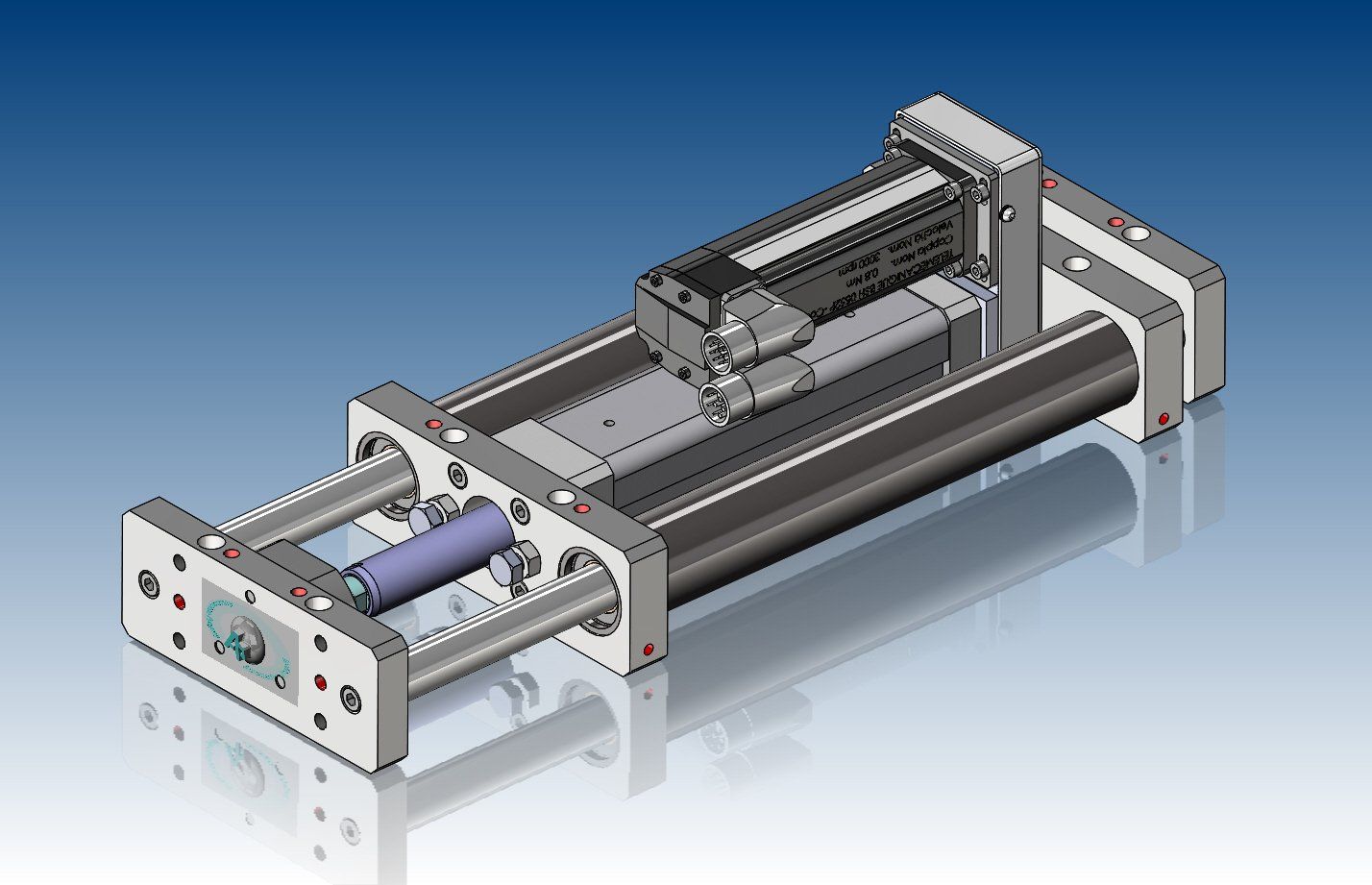

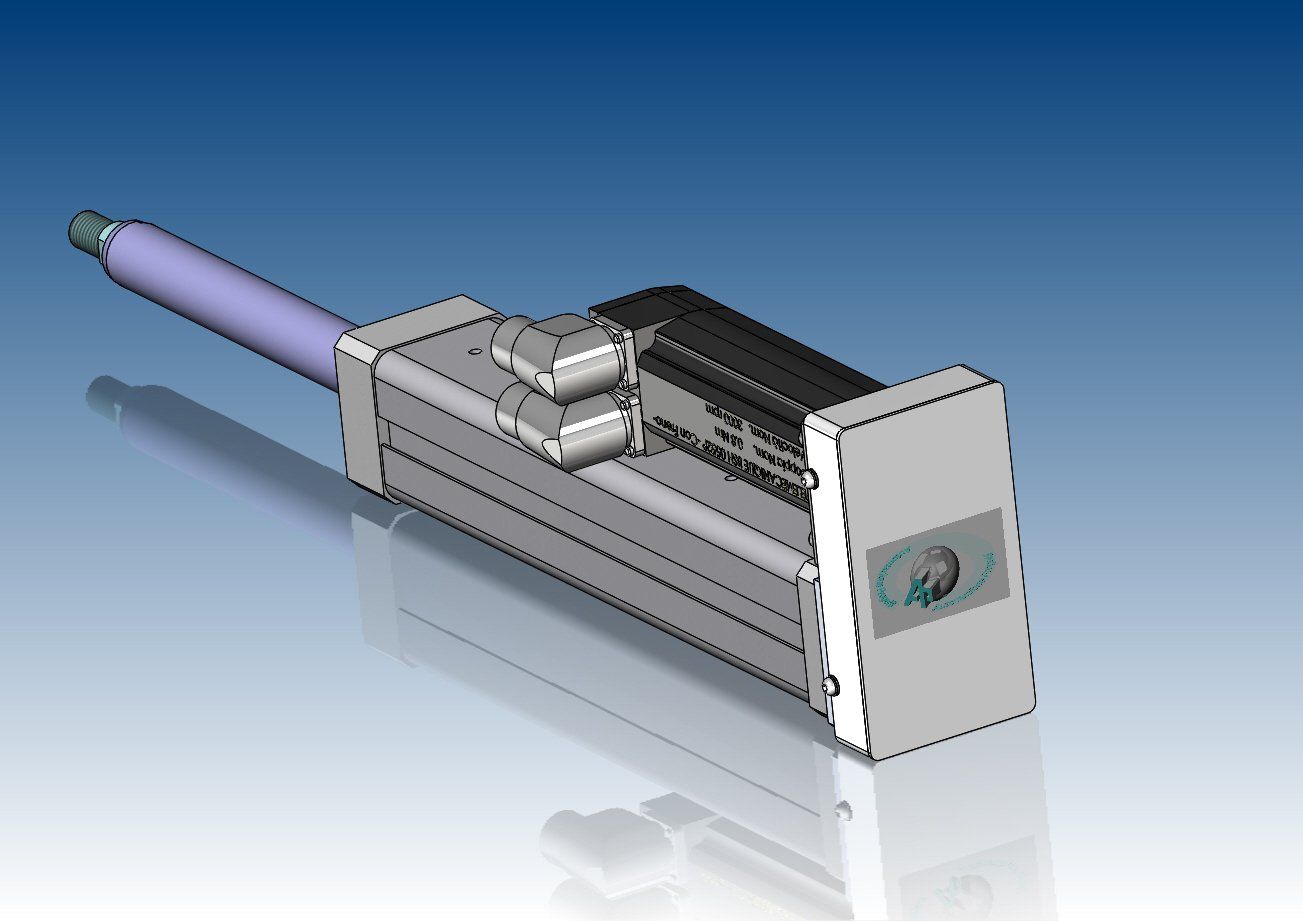

Standard electro cylinders Powered by a commercial electric motor interchangeable with a commercial pneumatic cylinder, from the best European brands. ISO 6431 standard

Yes, you guessed right ...

How many times has it occurred to you to replace a pneumatic cylinder with an electro cylinder, just because the customer has added some intermediate position, or because in a new similar project you need more positions.

Today you can do it easily without having to review the initial project, thanks to the interchangeability between the two worlds, and if by chance you have also used the AP slide, everything will be perfectly compatible with the slide, maintaining the interchangeability and compactness of the system. .

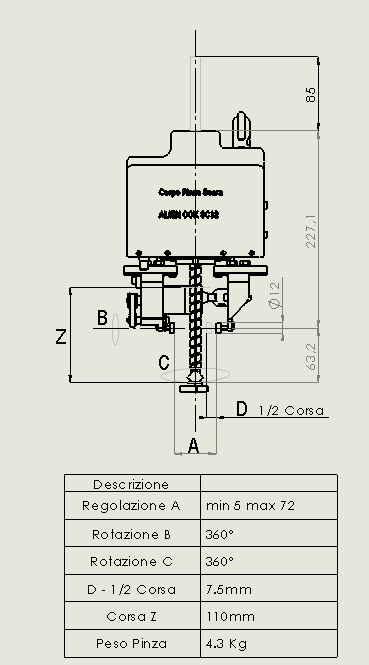

Flexible bracket for welding guns and torches to be combined with anthropomorphic robots

In a nutshell, we free axis 5 of anthropomorphic robots, which is the only axis of anthropomorphic robots to have 180 ° stroke limits. With the Flexible AP bracket, the total range of action of the Robot and the reachability of the points are consequently increased.

The gripper attachment system with flexible bracket simplifies the entire welding cycle by positioning the welding gun as an additional axis of an anthropomorphic robot, changing the gripper position from horizontal to vertical in a fraction of a second, avoiding unnecessary contortions of the robot, with the consequent loss of cycle time.

For many cases, the flexibility obtained saves expensive mobile equipment that retains and handles the elements to be welded.

This solution considerably simplifies all the CAD simulation procedures, reducing the costs of structures. The intelligent flexible bracket, operated by a PNE on off cylinder, or by a brushless synchronous motor, allows interpolation with the axes of anthropomorphic and Cartesian robots, reducing cycle times lost for tool changes, and for the movements of additional axes that move the elements to be welded. Last but not least, with a single robot and a single welding gun, it is possible to carry out welding on completely different elements and equipment, even with elements positioned vertically and horizontally.

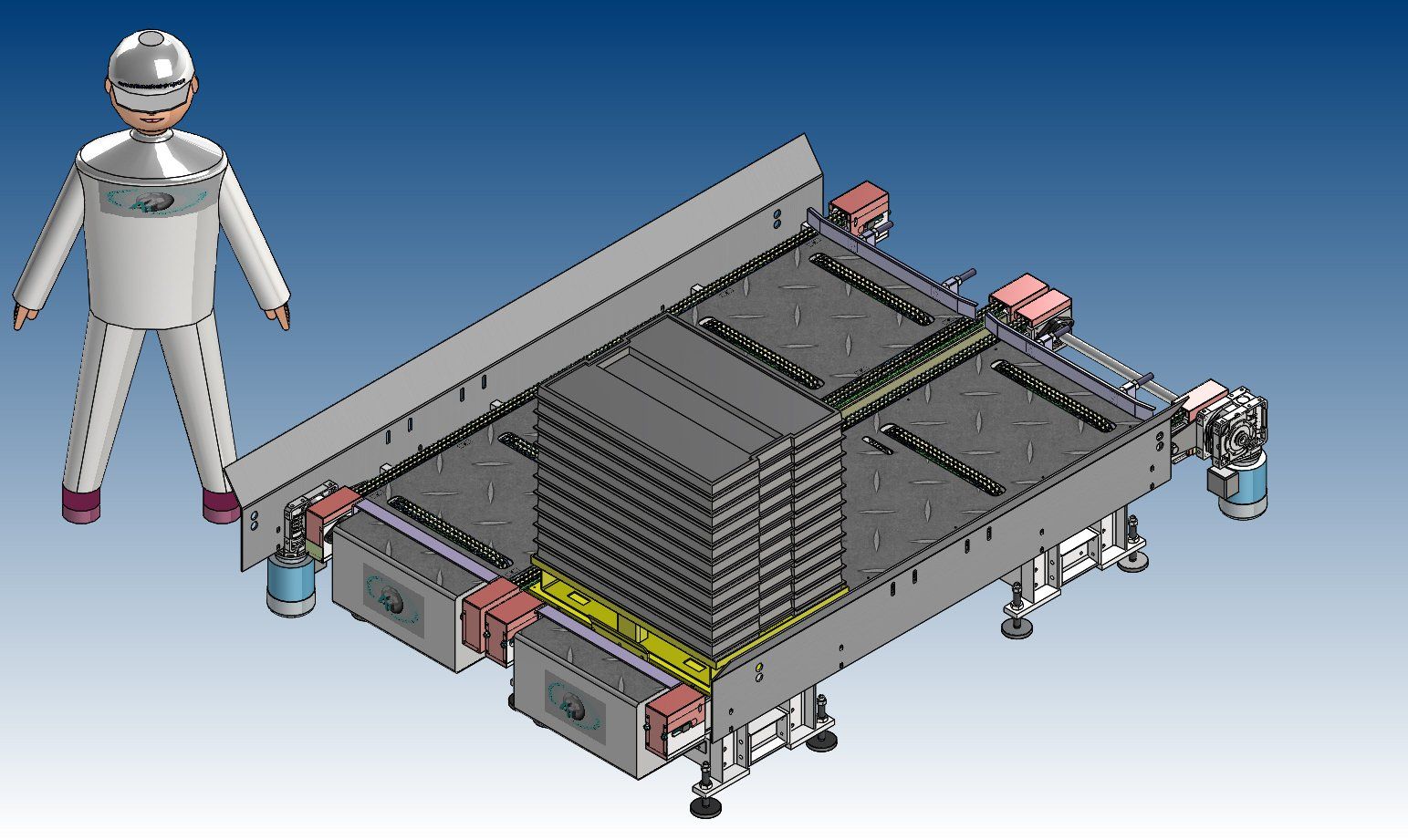

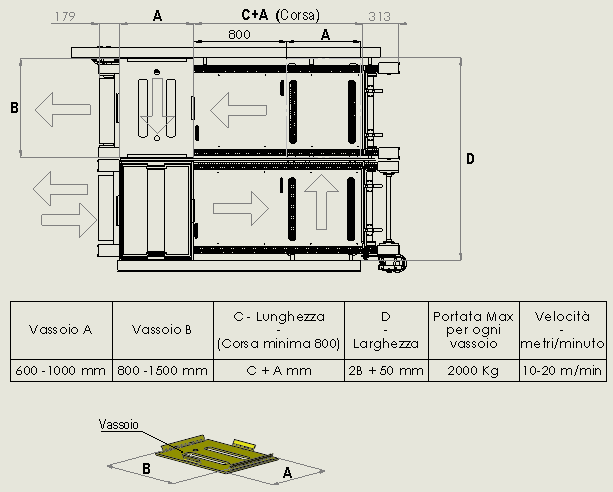

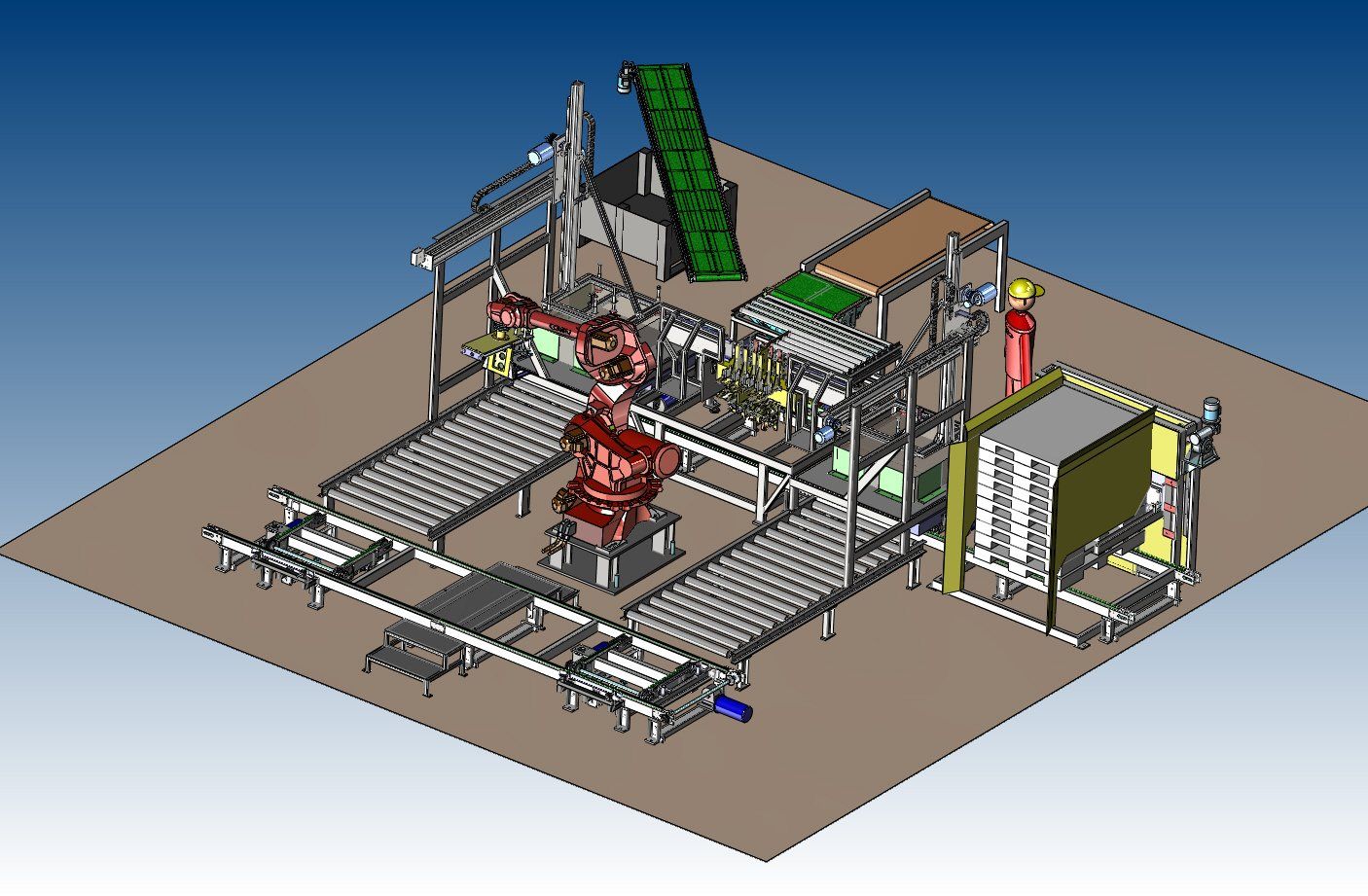

Warehouse for box recirculation. RECIRCULATION CONVEYORS FOR BOXES

The bin or platform recirculation system (Euro Pallet) is a need that the market has been demanding since the intelligent Robotized Bin Picking systems were developed, where the Robots, using advanced 3D vision systems, pick up the bulk items directly from the bins, so have a standardized bin or pallet recirculation system, another process that greatly simplifies automation.

AP designs and develops the system in the automotive sector, for the recirculation of pallets with preformed layer pads, but as for all AP products, the same system is used in all the sectors listed from clean rooms to cement factories, developing the same product for both Boxes that for Euro Pallet.

Creating a standard for conveyor belts seems trivial when used in just one industry.

Read the tricks and experiences made in the various fields, to adapt the product to all sectors.

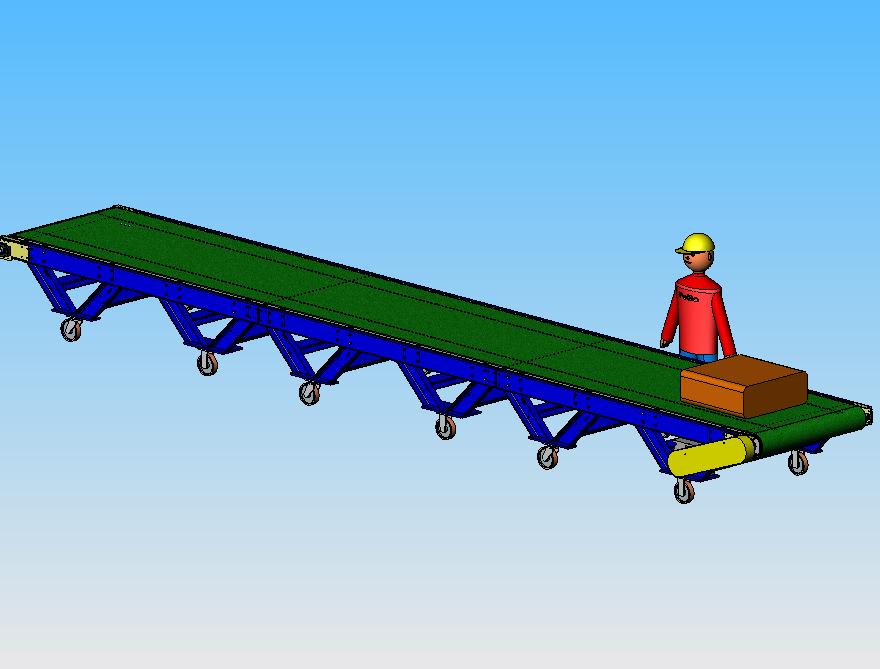

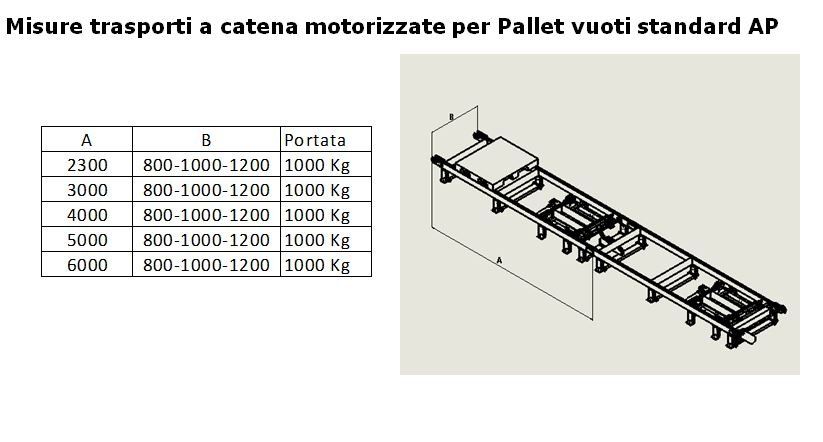

Roller Conveyors - Chains for Euro Pallet COMPONIBLE STANDARD ROLLER CONVEYORS

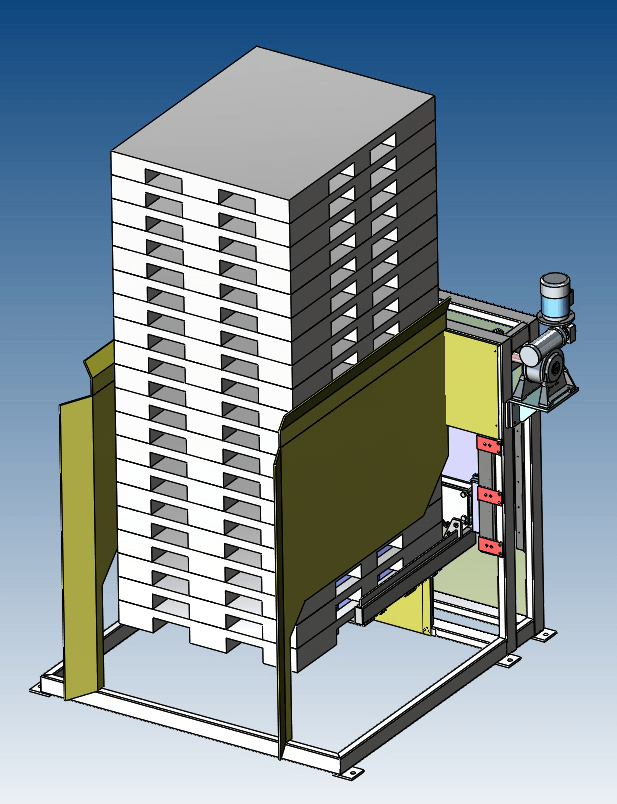

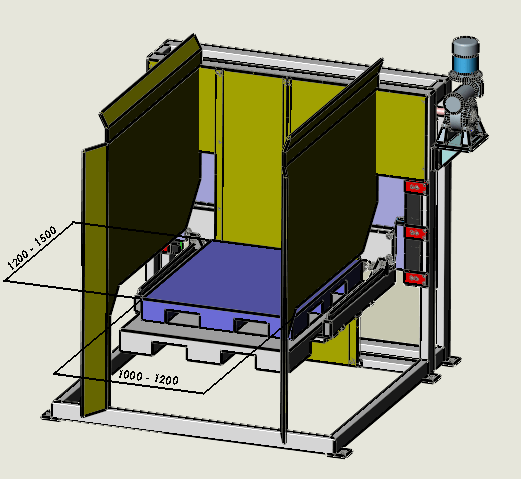

Euro Pallet Sheeters VERTICAL WAREHOUSE FOR EUROPALLETS WITH SHEETER

Universal vertical warehouse for Euro pallets Wood, Plastic.

Grippers for robots with 3 - 5 motorized interpolated axes

Grippers for robots, taken by Bin Picking with automatically oriented pre-determined element position.

Gripper elements to be combined with Anthropomorphic or Cartesian Robots, for direct bulk picking with element positioning during installation, automatic action with time masked by the movement of the robot between gripping and installation.

Bin Picking Standard Station. Artificial intelligence

Bin Picking Standard Station including horizontal axis and 3d camera

Standard stations for Bin Pickig, including standard station with motorized linear axis for moving 3D cameras to cover the surface of two or more bins, for anthropomorphic robots of all brands.

Electro Magnetic Grippers for Robots

Electromagnetic grippers for robots

Series of single or multiple Electromagnetic Grippers for anthropomorphic or Cartesian robots, with gripping force from 1Kg up to 1000Kg.

Possibility of radial gripping also on iron cylinders or pipes.

Automation products

Making Automation in all sectors listed for 30 years now requires very in-depth and specific organizational and structural skills, because each automation project is unique for the needs of the customer and the sector.

One of the secrets to keep the company dynamic in all sectors is certainly the company organization (click on the text "Courses")

offered by AP, where in the “Methods” chapter it is advisable to standardize as much as possible, deriving products from your automations, designing them already with the intention of making them standard products for current, future and sectoral automation.

Deriving products means having a foresight of product applications to make automation designs simple, intuitive and effective, but above all in the use of standardized products, well-tested over time in the applied sectors, which often generate copy and paste in future automation design , even in new sectors.

Automation by definition can never be a standard, because it is suited to the needs of the customer and the sector, and for this reason it must be accompanied by a multitude of products and parts of automation specially standardized.

In many years of activity, AP has designed a series of products by inserting and using them in its automations, which today it offers on the market, guaranteeing many economic, structural and organizational advantages, making the automation a set of multitudes products designed in doc, considerably simplifying the designs of automation, in the use of standard products, benefits that will consequently also have the final customer in finding spare parts, maintenance, facilitated supply over time, and not subject to variations dictated by the various commercial brands, using instead the commercial products in accordance with the suitable use that benefits both the automation manufacturer and the end customer.